Composite Materials

Composite materials are made by combining two or more different types of materials to create a new material with enhanced properties. These materials are used in a wide range of applications, from aerospace and automotive industries to construction and sports equipment.

Types of Composite Materials

There are three main types of composite materials:

- Polymer Matrix Composites (PMCs): These composites consist of a polymer resin matrix reinforced with fibers such as glass, carbon, or aramid.

- Metal Matrix Composites (MMCs): In MMCs, a metal matrix is reinforced with ceramic or carbon fibers to improve strength and stiffness.

- Ceramic Matrix Composites (CMCs): CMCs are made of a ceramic matrix reinforced with ceramic fibers, offering high-temperature resistance and durability.

Properties of Composite Materials

Composite materials exhibit a combination of properties that are superior to those of individual constituent materials. Some of the key properties include:

- Strength: Composites are often stronger than the individual materials they are made of, making them ideal for structural applications.

- Lightweight: Many composites are lightweight, which is advantageous in industries such as aerospace and automotive, where reducing weight can improve fuel efficiency and performance.

- Corrosion Resistance: Certain composite materials offer excellent resistance to corrosion, extending the lifespan of components.

- Flexibility and Design Freedom: Composites can be molded into complex shapes, providing design flexibility and the ability to create parts with specific performance characteristics.

Applications of Composite Materials

Composite materials are used in a wide variety of applications, including:

- Aerospace: Composites are used in aircraft components, such as wings, fuselage panels, and interior structures, to reduce weight and improve fuel efficiency.

- Automotive: Many modern cars utilize composites in body panels, chassis components, and interior parts to reduce weight while maintaining strength and safety.

- Construction: Composites are employed in building materials, bridges, and infrastructure for their durability and resistance to environmental factors.

- Sports Equipment: Composite materials are found in golf clubs, tennis rackets, bicycles, and athletic gear due to their lightweight and high-performance properties.

Study Guide for Composite Materials

When studying composite materials, it's important to understand the following concepts:

- The types of composite materials and their respective reinforcement fibers.

- The properties that make composites advantageous for various applications.

- The manufacturing processes used to create composite materials, such as molding, filament winding, and lay-up techniques.

- The environmental and economic benefits of using composite materials.

- Real-world examples of composite materials in use, including specific applications in different industries.

By understanding these concepts, you will gain a comprehensive understanding of composite materials and their significance in modern engineering and manufacturing.

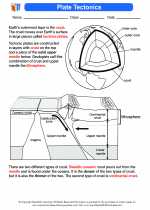

.◂Science Worksheets and Study Guides Eighth Grade. Plate tectonics

Activity Lesson

Activity Lesson

Worksheet/Answer key

Worksheet/Answer key

Worksheet/Answer key

Worksheet/Answer key

Worksheet/Answer key

Worksheet/Answer key

Worksheet/Answer key

Worksheet/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key

Vocabulary/Answer key